Planetary ball mills - function principle

In a planetary ball mill, each jar represents a “planet”. This planet is located on a circular platform, the so-called sun wheel. When the sun wheel turns, the jar rotates around its own axis, but in the opposite direction. Thus, centrifugal and Coriolis forces are activated, leading to a rapid acceleration of the grinding balls. The result is very high pulverization energy required to produce very fine particles. The enormous acceleration of the grinding balls from one wall of the jar to the other produces a strong impact effect on the sample material and leads to additional size reduction effects through friction.

For colloidal milling and most other applications, the ratio between the speed of the sun wheel and the speed of the grinding jar is 1: 2. This means that during one rotation of the sun wheel, the grinding jar rotates twice in the opposite direction. This speed ratio is very common for Planetary Ball Mills in general. Planetary ball mills with higher energy input and a speed ratio of 1:2.5 or even 1:3 are mainly used for mechanochemical applications.

Planetary ball mills - Fields of application

Planetary ball mills are used for the pulverization of soft, hard, brittle, and fibrous materials in dry and wet mode. Extremely high centrifugal forces result in very high pulverization energy and therefore short processing times.

Planetary ball mills are ideally suited for tasks in research like mechanochemistry (mechano-synthesis, mechanical alloying and mechanocatalysis), or ultrafine colloidal grinding on a nanometer scale, as well as for routine tasks such as mixing and homogenizing. Another field of application is screening of co-crystals, e. g. in the pharmaceutical industry.

A crucial advantage of planetary ball mills is their great versatility. They are available with different numbers of grinding stations. Jars and balls are available in various sizes and materials.

Full Models of Planetary Ball Mill at Your Options

According to functions of the machine, there are four types of planetary ball mill which are called vertical planetary ball mill, horizontal planetary ball mill, full-directional planetary ball mill, and dual planetary ball mill. You have to make right selection of the correspondent type according to requests of material grinding. All models of planetary can be equipped with cooling or warming device if necessary.

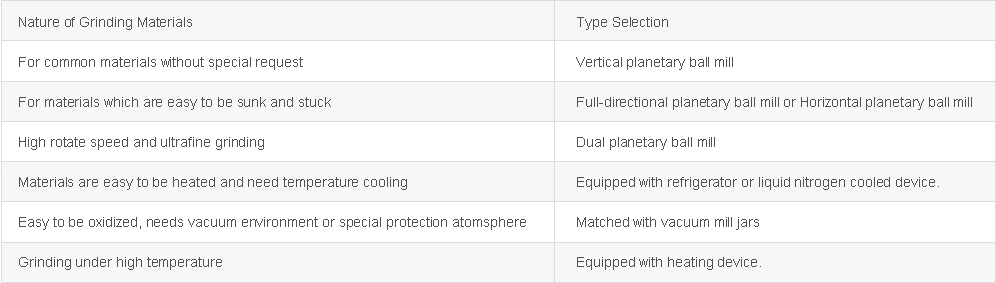

Reference Table For Type Selection of Planetary Ball Mill

Vertical Planetary Ball Mill |

Full-directional Planetary Ball Mill |

Horizontal Planetary Ball Mill |

Dual Planetary Ball Mill |

Selections of Grinding Balls

Selection of mill balls has to made based on the following factors:

1) Material of mill balls has no impurity to grinding materials;

2) Properties of ball's material such as anti high temperature, wear

resistance, and corrosion resistance have to meet request of grinding

process;

3) Density and hardness of balls has to be higher than that of grinding materials;

4) You are suggested to make selection as per the following matching table.

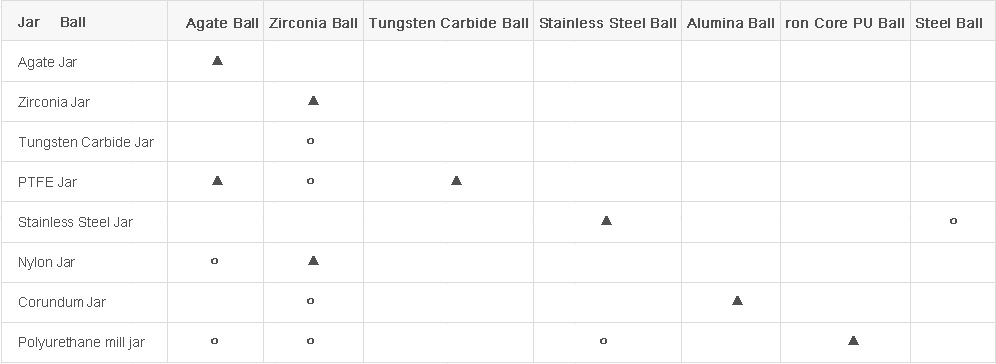

Matching Table for Jars & Balls

Notes:

▲ means Best'c ○ means Suitable

Ball Size Ratio in weight:

Ball Size Ratio in weight: Best ratio should be: large- sized balls 20%,

medium-sized balls:50%; small-sized balls: 30%

Tungsten carbide balls and zirconia balls are suitable for tungsten carbide jars

Polyurethane mill jar can be matched with iron core PU balls, agate balls, stainless steel balls, and zirconia balls.

Stainless steel mill jar can be matched with stainless steel balls and steel balls