Working Principle:

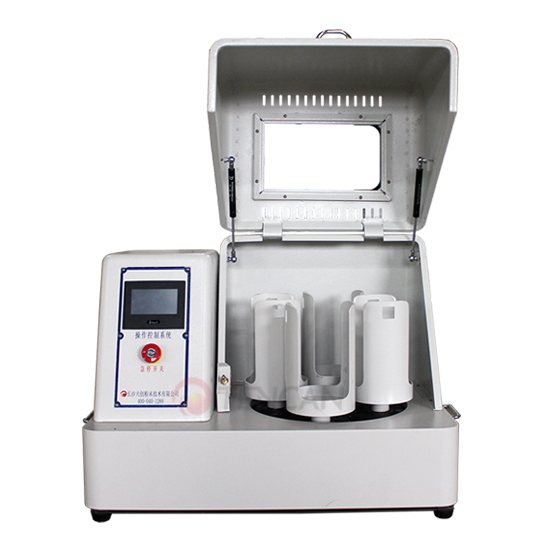

Planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements and the balls in the tanks grinds and mixes samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground products can be as small as 0.1 micron meter.

Applications:

Microcomputer touch screen planetary ball mill applies to the production fields of electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, lithium manganese oxide catalyst, phosphors, rare earth polishing powder, glass powder electronics, fuel cells, zinc oxide varistors, piezoelectric ceramics, nano-materials, disc ceramic capacitors, MLCC, dielectric ceramics, alumina ceramics, zirconia ceramics, phosphors, feed zinc oxide, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite products.

Feature:

1.Strong function of control system.

2.Provided with many functions such as the setting of password, freely programming, multiprogram storage and transfer, process monitoring and failure warning.

3.Visualized touching operation, simple and humanized design.

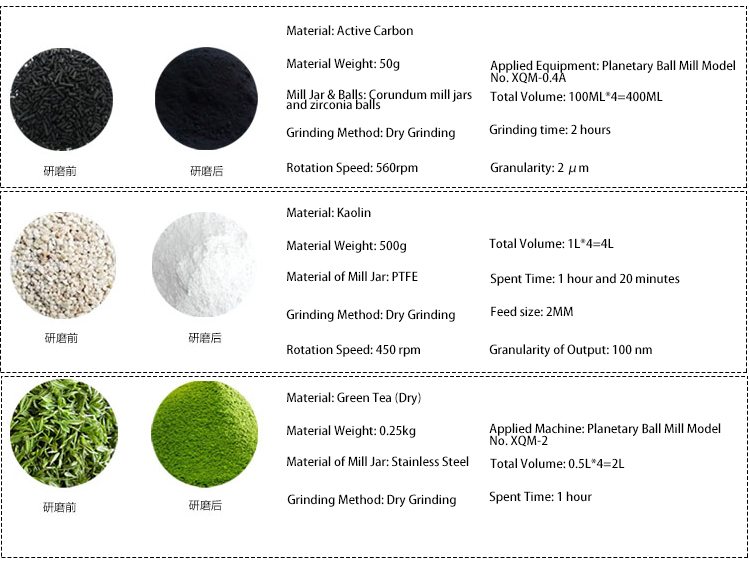

Application Cases of Planetary Ball Mill:

Test Report of Grinding Granularity by Planetary Ball Mill:

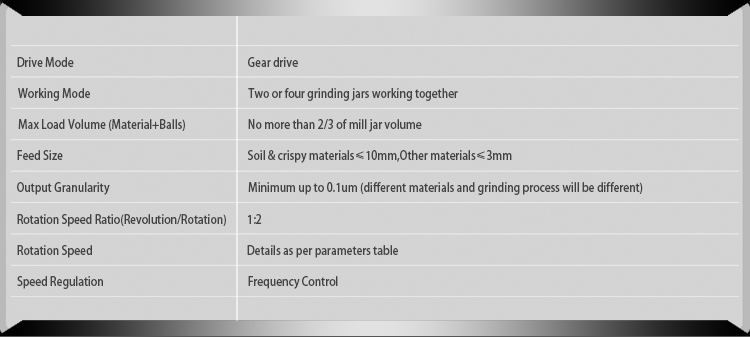

Application Parameters

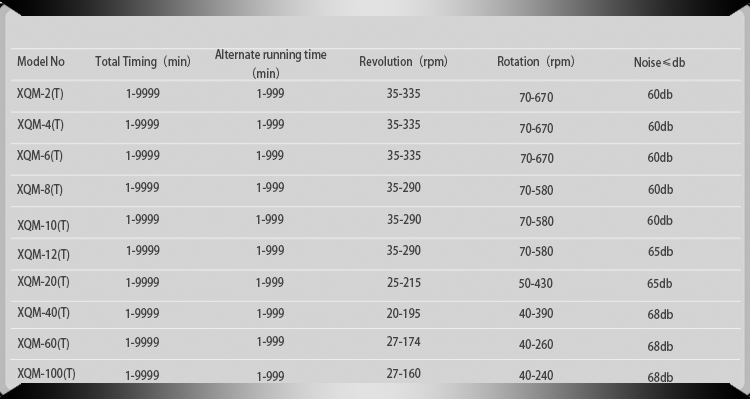

Parameters of Micro-computerized Planetary Ball Mill

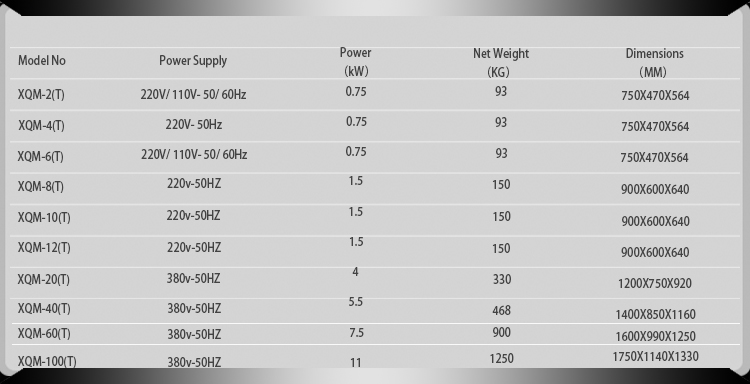

Measurement of Micro-computerized Planetary Ball Mill

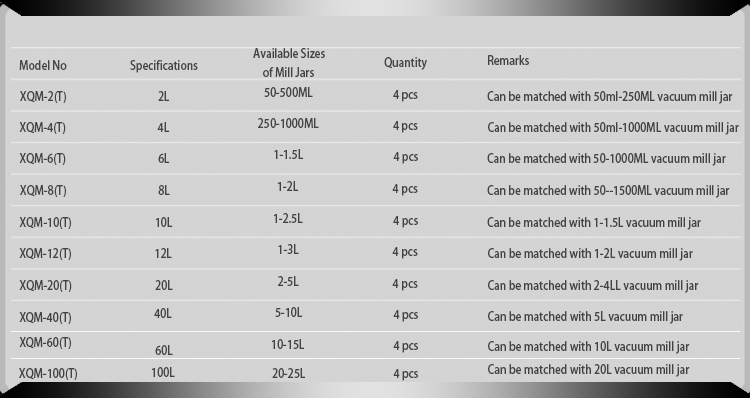

Available Sizes of Mill Jar for Micro-computerized Planetary Ball Mill

Mill Jars and Mill Balls:

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

1.Mill Jars:

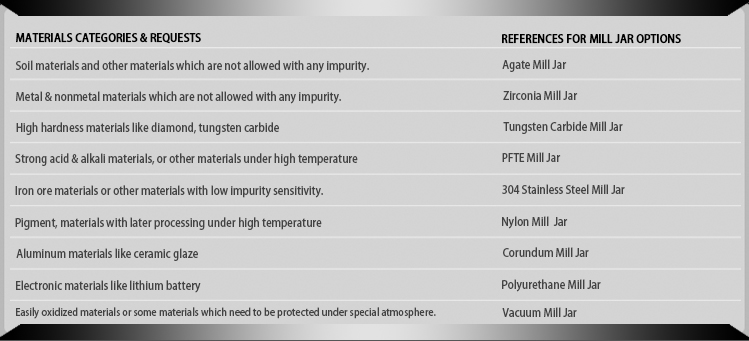

Suggestions for Matching Solution About Mill Jars & Materials:

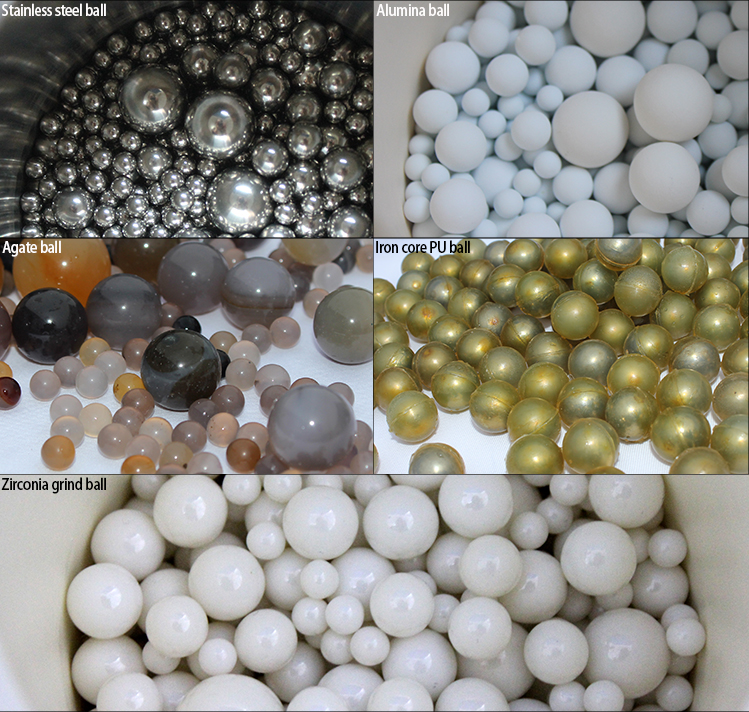

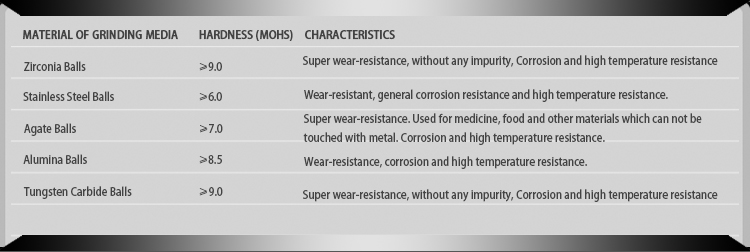

2.Mill Balls:

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Suggestions for Matching Solution About Grinding Medium & Materials:

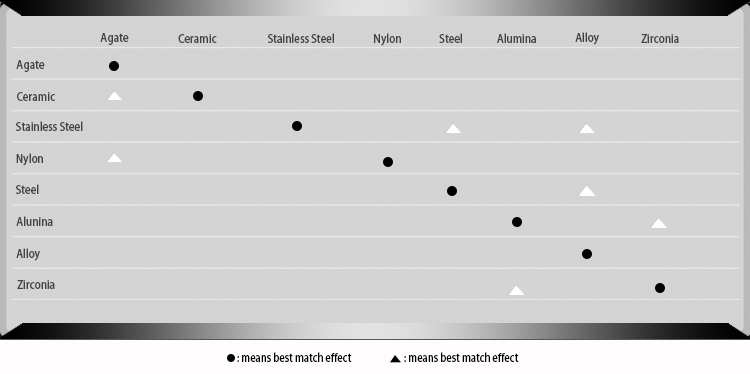

Suggestions for Matching Solution About Mill Jars & Mill balls:

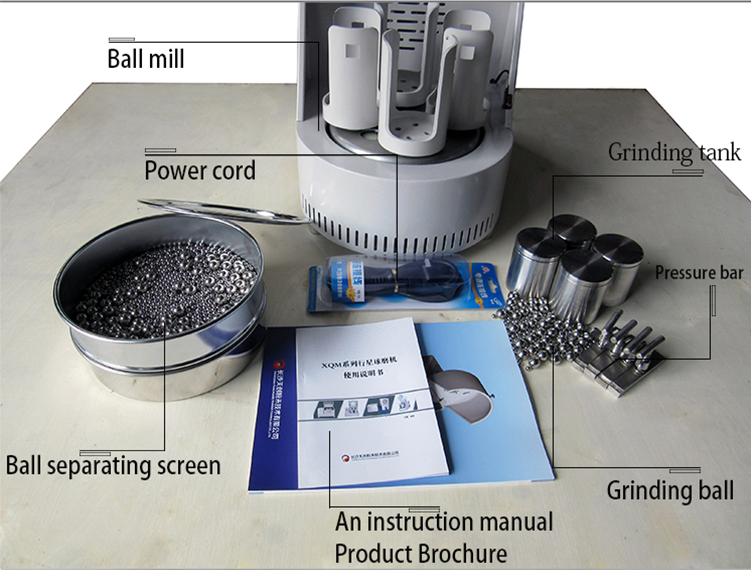

3.Pictures of Accessories & Spare Parts: