Lab Jar Mills' update iteration history

First generation (1950s-1970s):

An old roller-type machine, the tank body was loaded and unloaded manually, and was mainly used for coarse grinding of minerals, soil, ceramic pigments, paints, etc. at that time.

Second generation (1980s-2000s):

The second-generation pipe mill has begun to use motor drive, and the rotation speed can be adjusted by itself, and tank bodies of various materials (stainless steel tanks, nylon tanks, etc.) have been developed.

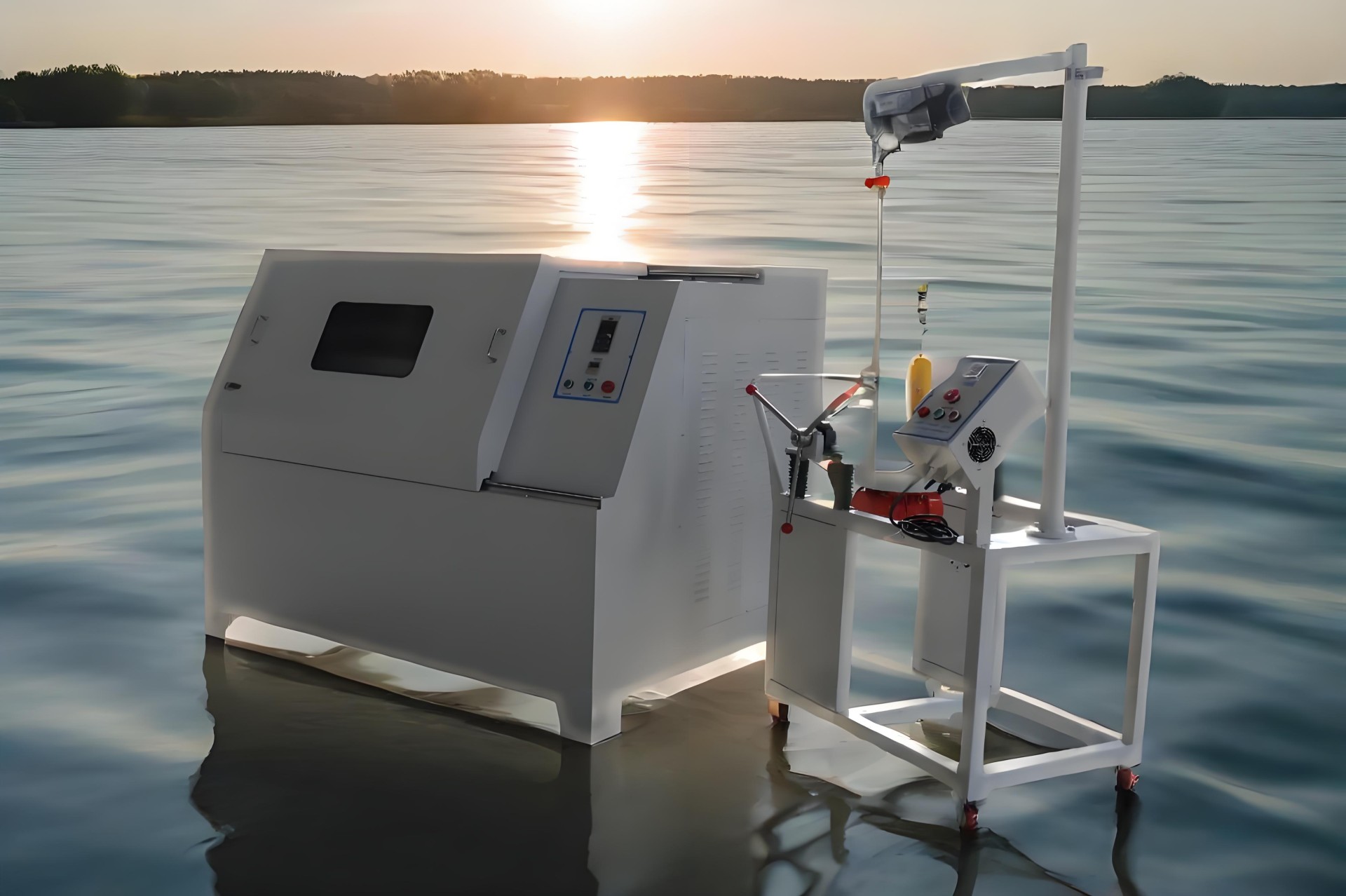

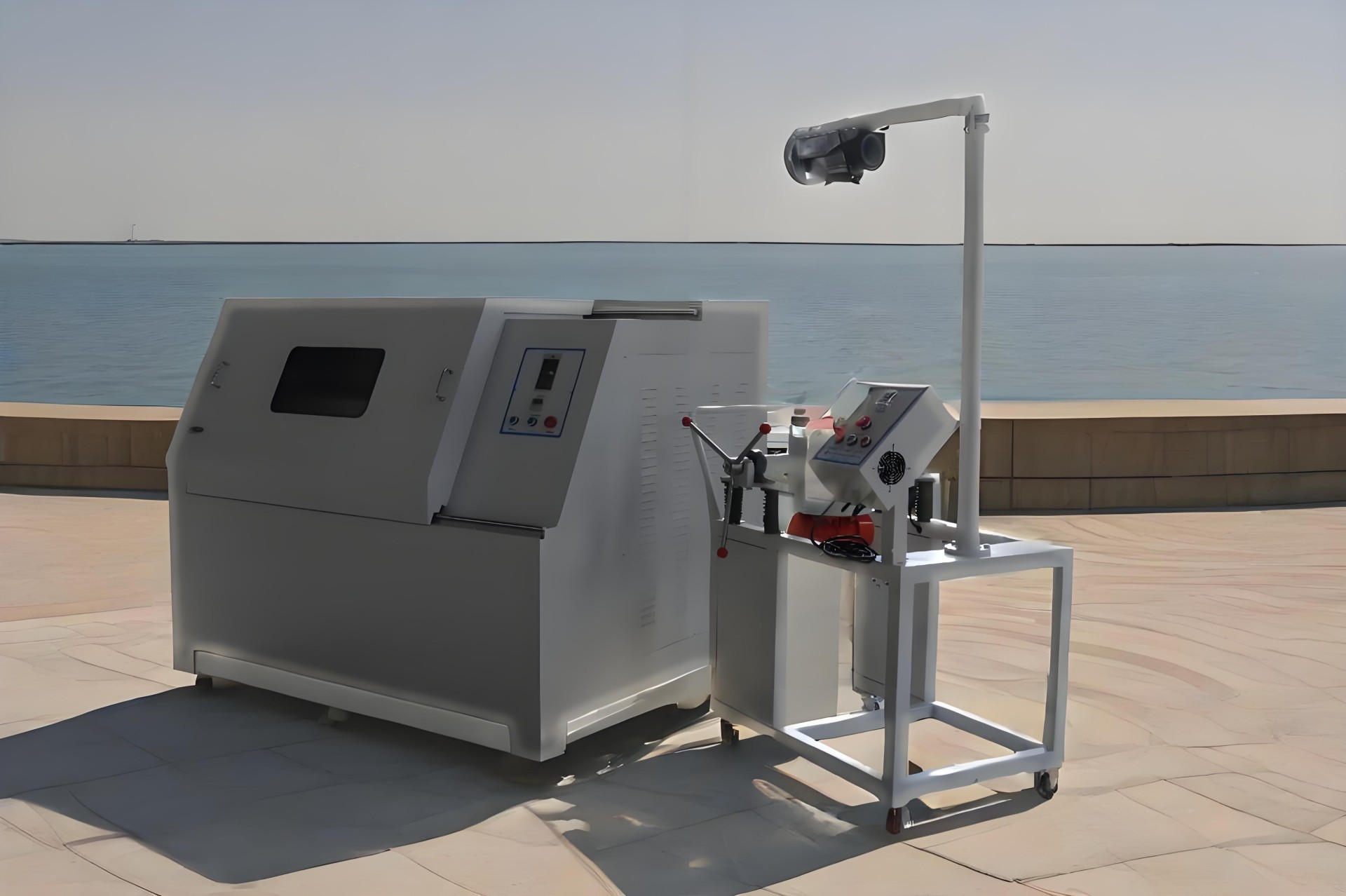

The third generation (2010s-to-present):

Intelligent laboratory tank mill: intelligent digital control system, autonomous timing, intelligent safety lock.

Nano-scale grinding capability, adapted to vacuum/inert gas/low temperature grinding and other environments.

Classification by abrasive particle size

Granularity range Applicable models Typical applications

>100 μm roller tank mill, ore, soil stone ceramics, etc. crush

10–100 μm Common Lab Jar Mill Metal Alloys, Ceramic Powders, Coatings, Pigments, etc.

<10 μm Nanoscale high-energy grinding type Preparation of drug nano-transformation, quantum dots, etc.

Why Choose Our Lab Jar Mills?

✅ High grinding control accuracy: digitally adjustable speed (50–600 RPM), ensuring controllable grinding accuracy.

✅ Functional diversity: Supports dry grinding, wet grinding, low temperature grinding, vacuum grinding (multiple grinding options are available).

✅ Little material pollution: A variety of tanks and grinding balls can be optional to avoid contamination of related products.

✅ Good silentness: operating noise <55 dB, suitable for laboratory environment.

✅ Good safety: motor overload protection and automatic power outage, good sealing to prevent leakage

Lab Jar Mills is widely used in laboratory grinding for its efficient grinding and mixing, and has applications in various scientific and industrial fields.

In the materials science industry, it is mainly used for homogenization of metal alloys, ceramic materials and composite materials. The advantage is that the particle size of the treatment sample is relatively consistent, which facilitates the replicability of subsequent experiments.

Lab Jar Mills, the pharmaceutical industry, has completed the micronization of drug active ingredients (API), which can effectively improve the solubility and bioavailability of materials and meet the strict GMP standards of the pharmaceutical industry.

Geological and environmental science application, this equipment is widely used in crushing ore, soil and other samples, and is used for the analysis of material composition.

New energy field: It is used to prepare the positive and negative electrode materials of lithium batteries, and refined abrasive materials can effectively improve the electrode performance.

In addition, in food and agriculture research, Lab Jar Mills can also be used to efficiently grind plants and soil, mineral extracts, spices, etc. to effectively preserve active ingredients.

Technical parameters (Comparison of key models)

Parameters Basic type High performance type Nano-level type

Maximum speed 300 RPM 600 RPM 800 RPM

Tank volume 250 mL–5 L 100 mL–2 L 50 mL–1 L

Material options Stainless steel, nylon Zirconium oxide, tungsten carbide PTFE, zirconium oxide

Special functions Timely shutdown Vacuum grinding Low temperature grinding (optional)

Why do users choose our Lab Jar Mills?

�� TENCAN tank mill has a longer service life: industrial-grade motor, with a design service life of 20% higher than other products under normal use.

�� TENCAN tank mill control is smarter: the speed, temperature and time are intelligently adjustable.

�� Global Service Network: 48 hours after-sales response.

�� Customization solution: There are a variety of tank bodies and modules to choose from. For specific needs, please contact us to customize (such as anti-static nylon).

Competitive product comparison

Features Our Lab Jar Mill Anonymous

Maximum speed 800 RPM 650 RPM 700 RPM

Noise level 55 dB 60 dB 58 dB

Intelligent control Touch screen + APP Mechanical knob Basic digital panel

Tank compatibility 6 materials Stainless steel/zirconia only 4 materials

Brand endorsement

�� Authoritative certification: CE, ISO 9001, etc.

�� Industry recognition: serving 20,000+ customers around the world and exporting to 60+ countries.

�� Customer witness:

“With your nanoscale Lab Jar Mill, the standard deviation of our drug preparations’ particle size distribution has been reduced by 30%.

——The R&D Director of an Unnamed Pharmaceutical Company (At Customer's Request)

FAQ (FAQ)

Q1: How to choose the right can material?

→ Choose stainless steel for metal samples, and choose zirconia/PTFE for sensitive materials.

Q2: How to prevent leakage during wet grinding?

→ Use silicone sealing ring + PTFE tank body, pressure self-locking design.

Q3: Can it be upgraded to vacuum grinding?

→ High-performance type supports optional vacuum module.

Call to Action (CTA)

Consult now for your exclusive guide

Email: tencan-ballmill@outlook.com

Whatsapp:8619974909729